Cable assembly

High-speed data, fiber optic, silicone, miniature, Single Pair Ethernet, rugged solutions: system-level engineering from technical drawings to industrialization

Full in-house capabilities to solve your connectivity challenges

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Full in-house capabilities to solve your connectivity challenges

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Full in-house capabilities to solve your connectivity challenges

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

The quality and construction of the cable, the cabling process and the cable length are key factors that directly impact the performances of the interconnect solution. The interface between the cabled connector and the device’s transmitter and receiver is also fundamental to guarantee that the whole system meets your industry standards and operational requirements.

Streamline your supply chain with our engineers and technical support teams for:

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

- Cable assembly design assistance

- Technical cable assembly drawings

- 100% electrical and sealing testing

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Our worldwide network ensures short production lead times and rapid delivery to meet your project deadline.

Key benefits

- Simplified supply chains and cost efficiency (up to -15-30%) through full-service approach

- Quick production turnaround through global footprint

- Tested and finished custom cable assemblies ready for installation

- Facilitated design process through system-level engineering

- Off-the-shelf pre-cabled connectivity solutions

Key benefits

- Simplified supply chains and cost efficiency (up to -15-30%) through full-service approach

- Quick production turnaround through global footprint

- Tested and finished custom cable assemblies ready for installation

- Facilitated design process through system-level engineering

- Off-the-shelf pre-cabled connectivity solutions

Key benefits

- Simplified supply chains and cost efficiency (up to -15-30%) through full-service approach

- Quick production turnaround through global footprint

- Tested and finished custom cable assemblies ready for installation

- Facilitated design process through system-level engineering

- Off-the-shelf pre-cabled connectivity solutions

Sales request

Key factors when working on an interconnect solution

- High-quality and cost-efficient techniques

- Size, weight and power (SWaP) requirements

- Unique signal & power configurations

- From prototyping to protocol compatibility

- System-level engineering, characterization and qualification

- Design simulation & testing

- For high-density miniaturization

- Ready for immediate integration test

- USB, Ethernet, Standard HD audio/video signals

- Assembly expertise

- Durable and harsh-environment designs

- High ingress protection (IP68)

- Cost- and space-effective solution

- Seamless integration and ruggedness

- Flexibility and versatility

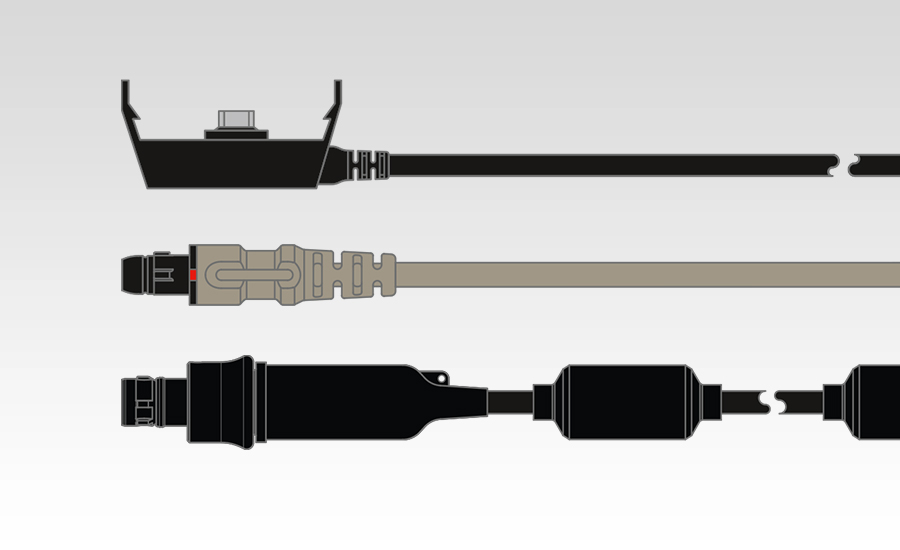

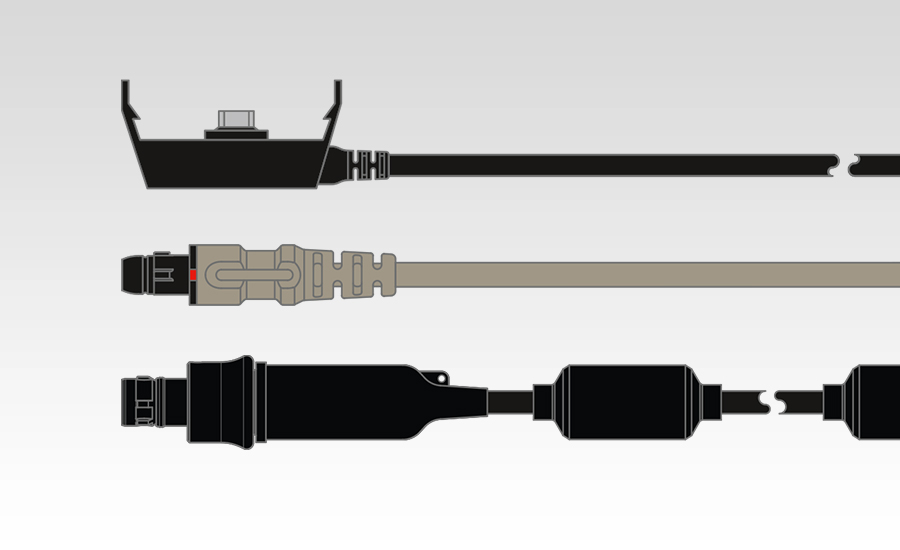

Our four-step process to tailor your cable assembly solution

1. Choose the ideal CONNECTOR for your application

- Fischer Core Series

- Fischer UltiMate™ Series

- Fischer FiberOptic Series

- Fischer MiniMax™ Series

2. Select the best CABLE TYPE

- Extreme environments – IP68 or hermetic sealing, ultra-resistant

- Medical – easy to clean, multiple sterilization methods

- Military – rugged, compact, lightweight

- Instrumentation – miniaturization, precision, high-speed data

- Fiber optic – broadcast, rodent-proof, sensing, copper-fiber hybrid

3. Get the right BEND RELIEF

- Pre-molded bend reliefs for fast delivery

- Thermoplastic overmolds to permanently bond connector and cable

- Silicone overmolds for silicone cables offering heat protection and maximum flexibility

- Custom overmolds with multi-cable exits

4. Choose the TERMINATION on the other end

- Fischer Connectors’ products

- Other standard connectors (Ethernet, USB, Audio/UHD Video)

- Custom connectors or electronic solutions

- Bluntcut / pigtail

Miniature & high-density cable assembly

Cabling miniature and dense connectors is extremely challenging and requires special technical know-how and specific tooling, assembly techniques and testing methods, well mastered by our operators. Miniaturization processes pertain to the entire chain of the cabling design and manufacture, including:

Miniature & high-density cable assembly

Cabling miniature and dense connectors is extremely challenging and requires special technical know-how and specific tooling, assembly techniques and testing methods, well mastered by our operators. Miniaturization processes pertain to the entire chain of the cabling design and manufacture, including:

Miniature & high-density cable assembly

Cabling miniature and dense connectors is extremely challenging and requires special technical know-how and specific tooling, assembly techniques and testing methods, well mastered by our operators. Miniaturization processes pertain to the entire chain of the cabling design and manufacture, including:

- Part alignment on both the plug and receptacle

- Bend relief cutting and cable jacket stripping

- Conductor back trimming and stripping

- Soldering, braid shielding, insulator tube and back nut potting

- O-ring and boot bend relief fixation, etc.

- Part alignment on both the plug and receptacle

- Bend relief cutting and cable jacket stripping

- Conductor back trimming and stripping

- Soldering, braid shielding, insulator tube and back nut potting

- O-ring and boot bend relief fixation, etc.

- Part alignment on both the plug and receptacle

- Bend relief cutting and cable jacket stripping

- Conductor back trimming and stripping

- Soldering, braid shielding, insulator tube and back nut potting

- O-ring and boot bend relief fixation, etc.

Leverage our expertise in miniaturization to design compact, lightweight and small-footprint cable assemblies that fulfill the shape, size, weight and power (SWaP) requirement of your device and electronic ecosystem.

Leverage our expertise in miniaturization to design compact, lightweight and small-footprint cable assemblies that fulfill the shape, size, weight and power (SWaP) requirement of your device and electronic ecosystem.

Leverage our expertise in miniaturization to design compact, lightweight and small-footprint cable assemblies that fulfill the shape, size, weight and power (SWaP) requirement of your device and electronic ecosystem.

High-speed data transmission

We assist you in creating high-speed connectivity solutions that are characterized and qualified with the most advanced design simulation and testing methods.

High-speed data transmission

We assist you in creating high-speed connectivity solutions that are characterized and qualified with the most advanced design simulation and testing methods.

High-speed data transmission

We assist you in creating high-speed connectivity solutions that are characterized and qualified with the most advanced design simulation and testing methods.

- High-reliability and high-performance technologies

- Optimal performances with minimal near-end crosstalk (NEXT) and far-end crosstalk (FEXT), insertion loss and return loss

- Ethernet up to 10 Gbit/s

- USB 3.2 Gen 2 up to 10 Gbit/s

- USB 2.0 up to 480 Mbit/s

- Audio/UHD Video

- High-reliability and high-performance technologies

- Optimal performances with minimal near-end crosstalk (NEXT) and far-end crosstalk (FEXT), insertion loss and return loss

- Ethernet up to 10 Gbit/s

- USB 3.2 Gen 2 up to 10 Gbit/s

- USB 2.0 up to 480 Mbit/s

- Audio/UHD Video

- High-reliability and high-performance technologies

- Optimal performances with minimal near-end crosstalk (NEXT) and far-end crosstalk (FEXT), insertion loss and return loss

- Ethernet up to 10 Gbit/s

- USB 3.2 Gen 2 up to 10 Gbit/s

- USB 2.0 up to 480 Mbit/s

- Audio/UHD Video

With our in-house capabilities in cable assembly and system engineering, we spare you the time of optimizing, simulating and testing your high-speed designs: we’ll take care of this, from prototyping to protocol compatibility.

With our in-house capabilities in cable assembly and system engineering, we spare you the time of optimizing, simulating and testing your high-speed designs: we’ll take care of this, from prototyping to protocol compatibility.

With our in-house capabilities in cable assembly and system engineering, we spare you the time of optimizing, simulating and testing your high-speed designs: we’ll take care of this, from prototyping to protocol compatibility.

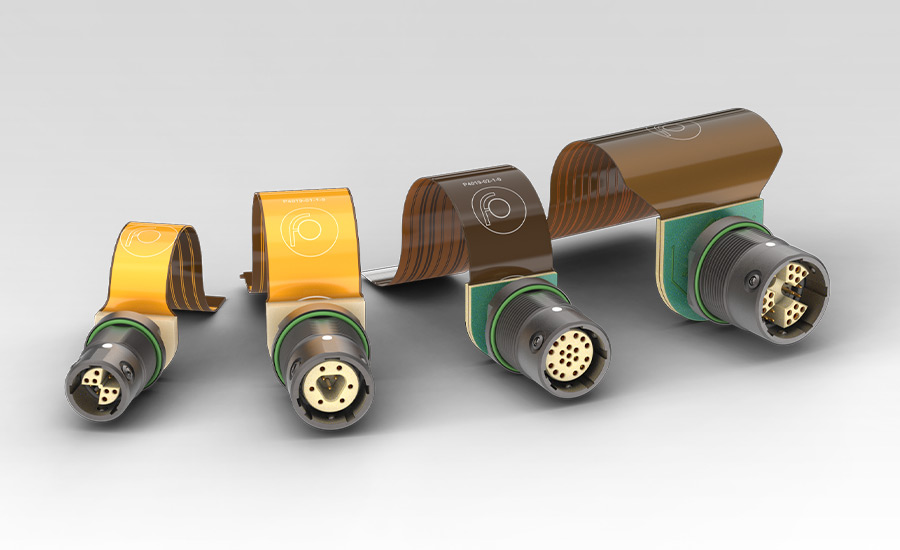

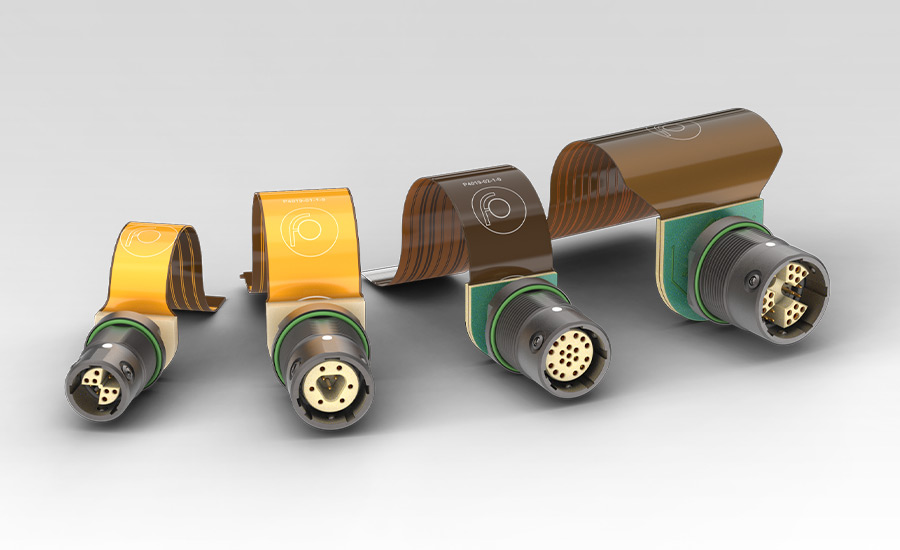

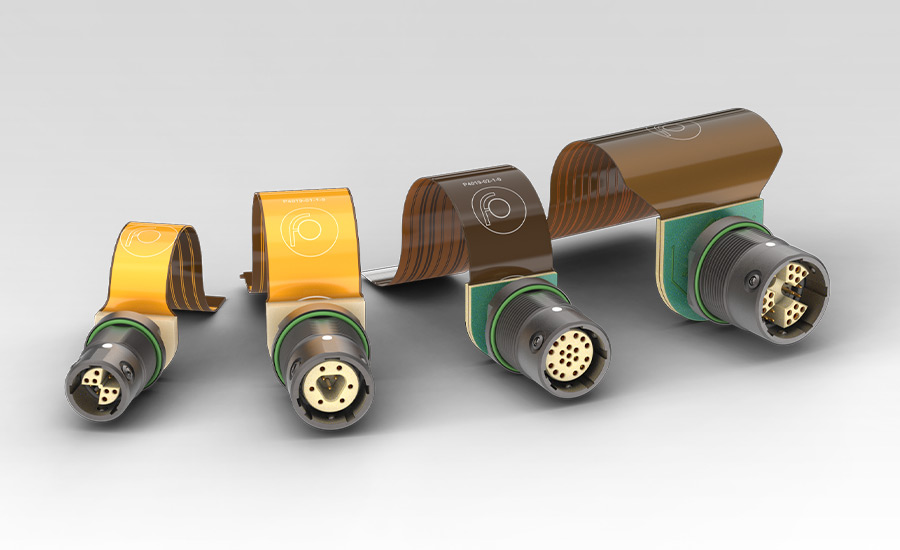

Flex circuit solutions

Our connector solutions assembled with prototype flex PCBs are designed to support high-density miniaturization and are ready for immediate integration test into your environments. Ideal for the initial development phases, these assemblies help streamline decision-making in the early stages of device design. They offer a fast and efficient way to evaluate connectivity functionalities in compact electronic systems with pinout compatibility for :

Flex circuit solutions

Our connector solutions assembled with prototype flex PCBs are designed to support high-density miniaturization and are ready for immediate integration test into your environments. Ideal for the initial development phases, these assemblies help streamline decision-making in the early stages of device design. They offer a fast and efficient way to evaluate connectivity functionalities in compact electronic systems with pinout compatibility for :

Flex circuit solutions

Our connector solutions assembled with prototype flex PCBs are designed to support high-density miniaturization and are ready for immediate integration test into your environments. Ideal for the initial development phases, these assemblies help streamline decision-making in the early stages of device design. They offer a fast and efficient way to evaluate connectivity functionalities in compact electronic systems with pinout compatibility for :

- USB

- Ethernet

- Standard HD audio/video signals

- USB

- Ethernet

- Standard HD audio/video signals

- USB

- Ethernet

- Standard HD audio/video signals

Silicone overmolding

Overmolds and heat-shrink tubing that provide sealing at the junction of the connector and the cable can impart functionality such as abrasion and impact resistance, low friction, vibration damping and protection from fluid ingress. One of the insulation materials available in rubber is silicone. It’s generally non-reactive, stable, resistant to extreme environments, and offers the widest thermal range (from -60 °C to 180 °C). Silicone cable assemblies thus stand up to any sterilization challenge you can throw at them: steam autoclave, high heat, disinfectants and sterilant solutions. Our wide range of silicone cable assemblies includes:

Silicone overmolding

Overmolds and heat-shrink tubing that provide sealing at the junction of the connector and the cable can impart functionality such as abrasion and impact resistance, low friction, vibration damping and protection from fluid ingress. One of the insulation materials available in rubber is silicone. It’s generally non-reactive, stable, resistant to extreme environments, and offers the widest thermal range (from -60 °C to 180 °C). Silicone cable assemblies thus stand up to any sterilization challenge you can throw at them: steam autoclave, high heat, disinfectants and sterilant solutions. Our wide range of silicone cable assemblies includes:

Silicone overmolding

Overmolds and heat-shrink tubing that provide sealing at the junction of the connector and the cable can impart functionality such as abrasion and impact resistance, low friction, vibration damping and protection from fluid ingress. One of the insulation materials available in rubber is silicone. It’s generally non-reactive, stable, resistant to extreme environments, and offers the widest thermal range (from -60 °C to 180 °C). Silicone cable assemblies thus stand up to any sterilization challenge you can throw at them: steam autoclave, high heat, disinfectants and sterilant solutions. Our wide range of silicone cable assemblies includes:

- Custom silicone overmolds

- Custom geometries

- Low-friction coating to prevent damage over the lifetime of the cable

- Custom colors available

- Custom silicone overmolds

- Custom geometries

- Low-friction coating to prevent damage over the lifetime of the cable

- Custom colors available

- Custom silicone overmolds

- Custom geometries

- Low-friction coating to prevent damage over the lifetime of the cable

- Custom colors available

The silicone overmolds from the Fischer Core Series in sizes 104 and 105 are medical cable assemblies tested to ISO 13485.

The silicone overmolds from the Fischer Core Series in sizes 104 and 105 are medical cable assemblies tested to ISO 13485.

The silicone overmolds from the Fischer Core Series in sizes 104 and 105 are medical cable assemblies tested to ISO 13485.

Military cable assembly

Military cable assemblies are specialized data & power cable systems designed and manufactured to meet the stringent requirements of the military and defense industries. These cable assemblies play a critical role in various military applications, including communication, data transfer, power distribution, and more.

Military cable assembly

Military cable assemblies are specialized data & power cable systems designed and manufactured to meet the stringent requirements of the military and defense industries. These cable assemblies play a critical role in various military applications, including communication, data transfer, power distribution, and more.

Military cable assembly

Military cable assemblies are specialized data & power cable systems designed and manufactured to meet the stringent requirements of the military and defense industries. These cable assemblies play a critical role in various military applications, including communication, data transfer, power distribution, and more.

- Built to withstand harsh environmental conditions

- Compatible with the latest military standards

- Highly customizable

- Built to withstand harsh environmental conditions

- Compatible with the latest military standards

- Highly customizable

- Built to withstand harsh environmental conditions

- Compatible with the latest military standards

- Highly customizable

Discover our portfolio based on the Fischer UltiMate™ 80.

Discover our portfolio based on the Fischer UltiMate™ 80.

Fiber optic cable assembly

To guarantee flawless data transmissions through fibers, the process of cutting, stripping and assembling fiber optic components must be performed with the highest precision and requires dedicated tooling, techniques, procedures, and craftsmanship.

The precise alignment and positioning of the fibers, as well as their preparation and outgassing, are particularly challenging tasks, and a meticulous execution is needed to reach best optical performances. Furthermore, only correctly cleaned fiber strands can prevent bad fusion splices and inadequate bonds. Our optical solutions offer:

Fiber optic cable assembly

To guarantee flawless data transmissions through fibers, the process of cutting, stripping and assembling fiber optic components must be performed with the highest precision and requires dedicated tooling, techniques, procedures, and craftsmanship.

The precise alignment and positioning of the fibers, as well as their preparation and outgassing, are particularly challenging tasks, and a meticulous execution is needed to reach best optical performances. Furthermore, only correctly cleaned fiber strands can prevent bad fusion splices and inadequate bonds. Our optical solutions offer:

Fiber optic cable assembly

To guarantee flawless data transmissions through fibers, the process of cutting, stripping and assembling fiber optic components must be performed with the highest precision and requires dedicated tooling, techniques, procedures, and craftsmanship.

The precise alignment and positioning of the fibers, as well as their preparation and outgassing, are particularly challenging tasks, and a meticulous execution is needed to reach best optical performances. Furthermore, only correctly cleaned fiber strands can prevent bad fusion splices and inadequate bonds. Our optical solutions offer:

- Optimal quality and stability of the optical link

- Designs enduring rough use in extreme outdoor conditions

- Easy use in the field

- Optimal quality and stability of the optical link

- Designs enduring rough use in extreme outdoor conditions

- Easy use in the field

- Optimal quality and stability of the optical link

- Designs enduring rough use in extreme outdoor conditions

- Easy use in the field

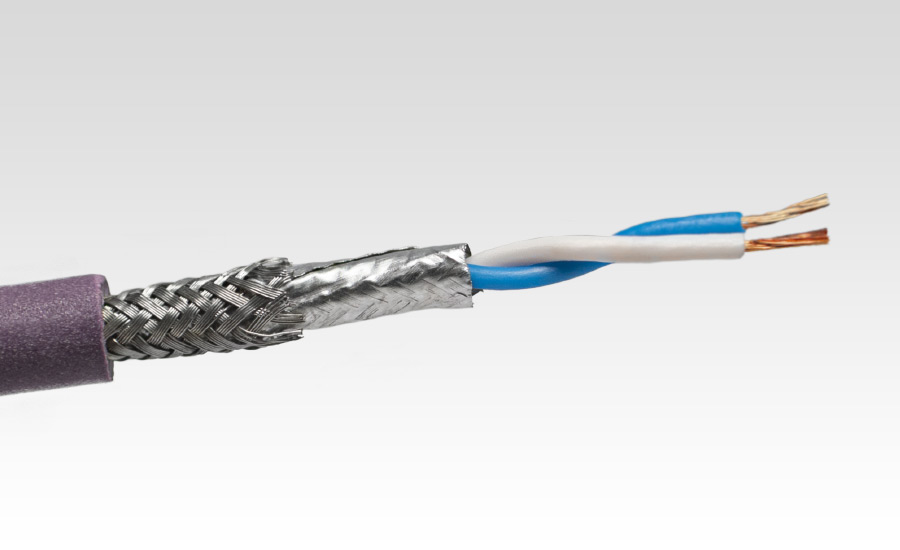

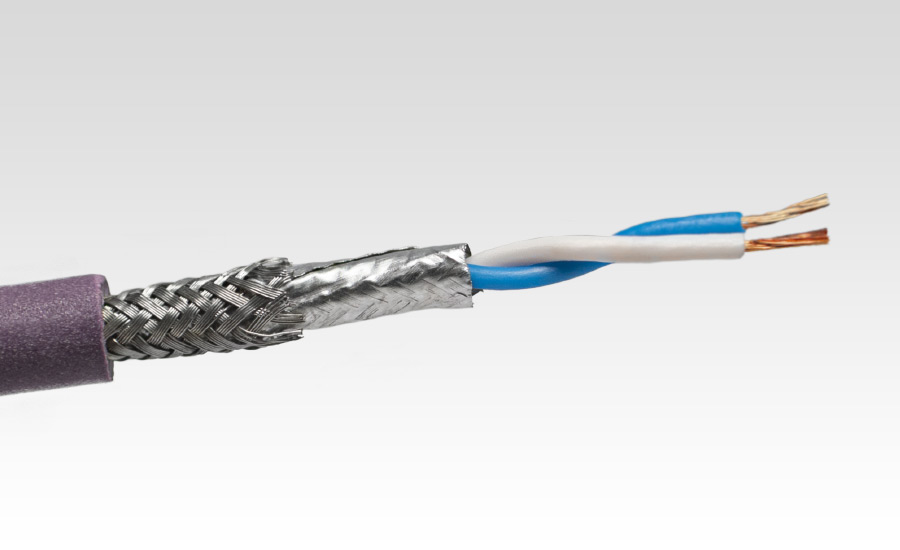

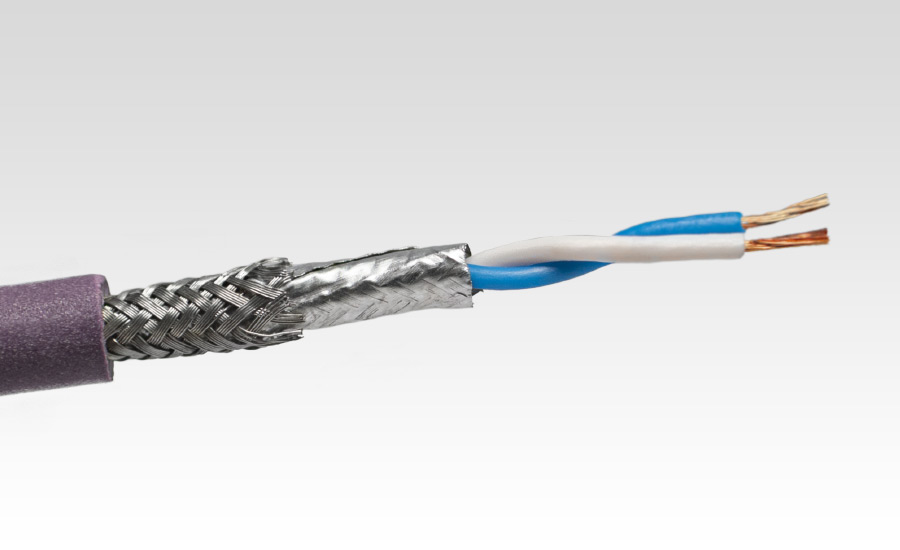

Single Pair Ethernet

The increasing density of sensors, actuators and controllers in networked devices used in industrial automation, transportation, smart cities and defense poses particular challenges in Ethernet connectivity, among which long cabling distances to cover, bandwidth limitations from legacy connectivity systems, and complexity from managing multiple protocols. These challenges have fueled the demand for a smaller, lighter and more affordable version of the Ethernet, the Single Pair Ethernet (SPE), which uses just one pair of twisted copper wires and offers:

Single Pair Ethernet

The increasing density of sensors, actuators and controllers in networked devices used in industrial automation, transportation, smart cities and defense poses particular challenges in Ethernet connectivity, among which long cabling distances to cover, bandwidth limitations from legacy connectivity systems, and complexity from managing multiple protocols. These challenges have fueled the demand for a smaller, lighter and more affordable version of the Ethernet, the Single Pair Ethernet (SPE), which uses just one pair of twisted copper wires and offers:

Single Pair Ethernet

The increasing density of sensors, actuators and controllers in networked devices used in industrial automation, transportation, smart cities and defense poses particular challenges in Ethernet connectivity, among which long cabling distances to cover, bandwidth limitations from legacy connectivity systems, and complexity from managing multiple protocols. These challenges have fueled the demand for a smaller, lighter and more affordable version of the Ethernet, the Single Pair Ethernet (SPE), which uses just one pair of twisted copper wires and offers:

- Data transmission at speeds ranging from 10 Mbit/s to 10 Gbit/s

- Power over Data Line (PoDL) up to 52 Watts

- Over distances from 15 meters (at 10, 100 and 1,000 Mbit/s) to 1,000 meters (at 10 Mbit/s)

- Data transmission at speeds ranging from 10 Mbit/s to 10 Gbit/s

- Power over Data Line (PoDL) up to 52 Watts

- Over distances from 15 meters (at 10, 100 and 1,000 Mbit/s) to 1,000 meters (at 10 Mbit/s)

- Data transmission at speeds ranging from 10 Mbit/s to 10 Gbit/s

- Power over Data Line (PoDL) up to 52 Watts

- Over distances from 15 meters (at 10, 100 and 1,000 Mbit/s) to 1,000 meters (at 10 Mbit/s)

In leveraging our technologies dedicated to applications requiring faultless precision, durability and resistance to extreme conditions, we combine SPE’s unique features with our high-reliability, high-performance, sealed connectors to take SPE connectivity to new application dimensions in industrial production lines and defense UAVs.

In leveraging our technologies dedicated to applications requiring faultless precision, durability and resistance to extreme conditions, we combine SPE’s unique features with our high-reliability, high-performance, sealed connectors to take SPE connectivity to new application dimensions in industrial production lines and defense UAVs.

In leveraging our technologies dedicated to applications requiring faultless precision, durability and resistance to extreme conditions, we combine SPE’s unique features with our high-reliability, high-performance, sealed connectors to take SPE connectivity to new application dimensions in industrial production lines and defense UAVs.

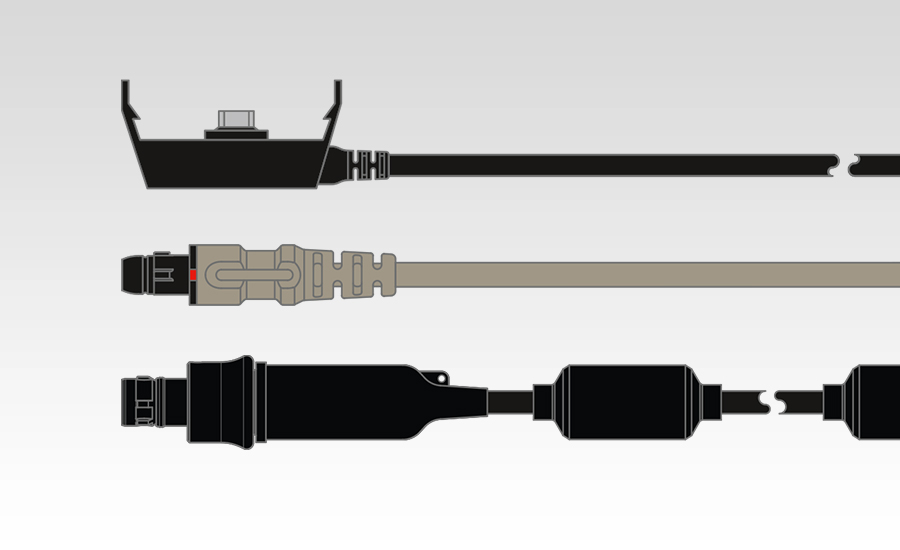

Optimized cabled solutions

No matter what stage of the design process you’re at, whether it be initial project sketches or fully defined design solutions, our experienced cable assembly engineers will work with you to help specify and select the proper materials and optimize the form, fit and function of a large variety of electrical, optical, fluid/gas and hybrid connections. Our engineers consider the end-use application and its environment and ecosystem as a whole, and integrate third-party connectors as well. Our capabilities include:

Optimized cabled solutions

No matter what stage of the design process you’re at, whether it be initial project sketches or fully defined design solutions, our experienced cable assembly engineers will work with you to help specify and select the proper materials and optimize the form, fit and function of a large variety of electrical, optical, fluid/gas and hybrid connections. Our engineers consider the end-use application and its environment and ecosystem as a whole, and integrate third-party connectors as well. Our capabilities include:

Optimized cabled solutions

No matter what stage of the design process you’re at, whether it be initial project sketches or fully defined design solutions, our experienced cable assembly engineers will work with you to help specify and select the proper materials and optimize the form, fit and function of a large variety of electrical, optical, fluid/gas and hybrid connections. Our engineers consider the end-use application and its environment and ecosystem as a whole, and integrate third-party connectors as well. Our capabilities include:

- Overmolded cable assemblies for bend protection (thermoplastic and silicone) and right-angled overmolds

- Wiring harness assemblies

- Internal potting enhancing sealing level to allow for submersion

- Heat shrinking for added protection and support to exposed wire

- Breakouts, pigtails, fiber optic termination

- Low cost and disposable options, etc.

- Overmolded cable assemblies for bend protection (thermoplastic and silicone) and right-angled overmolds

- Wiring harness assemblies

- Internal potting enhancing sealing level to allow for submersion

- Heat shrinking for added protection and support to exposed wire

- Breakouts, pigtails, fiber optic termination

- Low cost and disposable options, etc.

- Overmolded cable assemblies for bend protection (thermoplastic and silicone) and right-angled overmolds

- Wiring harness assemblies

- Internal potting enhancing sealing level to allow for submersion

- Heat shrinking for added protection and support to exposed wire

- Breakouts, pigtails, fiber optic termination

- Low cost and disposable options, etc.

Our solutions are compliant with the highest technology standards in terms of ruggedness, sealing and high-speed data transmission.

Our solutions are compliant with the highest technology standards in terms of ruggedness, sealing and high-speed data transmission.

Our solutions are compliant with the highest technology standards in terms of ruggedness, sealing and high-speed data transmission.

Discover our portfolio based on the Fischer UltiMate™ 80.