In IIoT applications, high-performance cables and connectors are required to enable high data transmission rates even over longer distances. Single Pair Ethernet is predestined for this. The new technology scores with many other advantages, such as low material and space requirements, and is therefore an indispensable part of highly automated industrial process chains in the future.

Single Pair Ethernet for IIoT: High-speed data transmission in small space

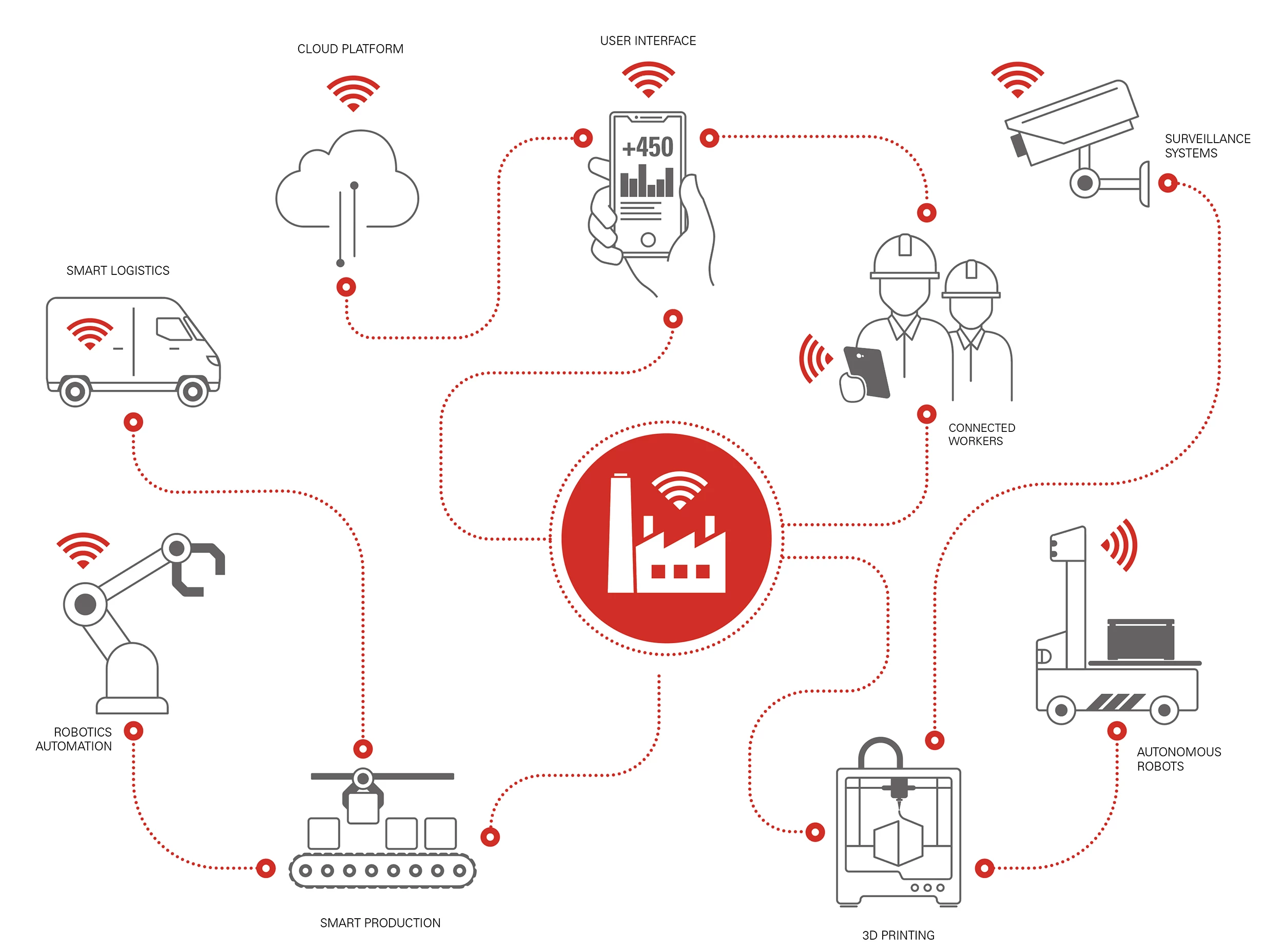

August 15, 2023 · 6 min readIndustrial value-creation processes are currently changing at an unprecedented pace, characterized as they are by maximum digitalization, automation and networking. All the components involved, such as machines, robots, controllers, transfer systems, industrial PCs, smart cameras and sensors, are communicating with each other end-to-end, consistently in line with Industry 4.0, and are constantly exchanging data – whether via internal connections or the Internet. The overriding goal of this Industrial Internet of Things (IIoT) is to make processes more consistent and faster, so as to improve the quality of products and increase cost efficiency.

IIoT market on course for growth

The increasing importance of IIoT is also confirmed by numerous studies. For example, in a representative survey, 72 percent of global manufacturing companies said they already had sound Industrie 4.0 strategies in place. Accordingly, companies are already investing heavily in corresponding technologies. The global IIoT market amounted to 293 billion euros in 2022 and is expected to grow by a further 20 to 25 percent per year until 2030. According to expert estimates, the IIoT segment will reach a market volume of EUR 1.5 trillion by then.

This trend is fueled by many factors, including the increasing availability of low-cost sensors, advanced networking technologies, and modern software solutions based on artificial intelligence (AI) and machine learning. Coupled with growing industrial globalization, these innovations have created an environment in which diverse actors such as manufacturing companies, their employees, suppliers, consumers, investors and other stakeholders can be connected anywhere, anytime – and at manageable cost. This is precisely the essence of modern IIoT scenarios.

High level of network connectivity is required

The technical implementation of IIoT requirements presupposes a special level of network connectivity that is unprecedented in the history of the industry. To date, various communication systems such as Profinet, CAT 5e and 6a, Industrial Ethernet or Ethercat have been used for this purpose. Ethernet continues to play a central role as a transmission technology. The increasing density of sensors, actuators and controllers in networked IIoT devices poses particular challenges for Ethernet connectivity. These include, for example, very long cabling distances, bandwidth limitations due to outdated connection technologies, and the complex management of various protocols.

These requirements have created the need for a compact, lightweight and cost-effective Ethernet variant. Single Pair Ethernet (SPE) has emerged as the solution of choice. Here, signals are transmitted via only one pair of twisted copper wires, which has several significant advantages. For example, a reduced need for cables significantly saves material, space and weight. Only two instead of eight wires require significantly less copper, enable smaller sensor systems and clear the way for miniaturization of industrial cable infrastructures. Thanks to compact and cost-effective cables with 35 to 50 percent less weight – compared to conventional Ethernet and fieldbus cables – considerable cost savings can be realized.

Transmission of power and data

A further decisive advantage: Single Pair Ethernet transmits data at a speed of up to 10 Gbit/s. In addition, the available space is used efficiently. One and the same pair of copper wires also serves to supply power to connected end devices with up to 52 watts (Power over Data Line, PoDL). Otherwise, two pairs of wires would be required for Fast Ethernet (100 MB) and four pairs for Gigabit Ethernet. In addition, Single Pair Ethernet paves the way for high-speed data transmission over comparatively long distances. The technology offers the potential for ten times the range and can transmit data over distances of up to 1,000 meters at a bandwidth of 10 Mbit/s. At a transmission rate of 1 Gbit/s, on the other hand, up to 40 meters can be bridged.

There are other advantages such as the high robustness and the resulting longevity of the connections. Moreover, SPE cables can be installed very quickly and easily to be integrated into factory infrastructures, which reduces material and labor costs. As a result, Single Pair Ethernet creates the best conditions for the development of high-performance and cost-effective industrial connectivity solutions. These combine the advantages of high-speed data transmission with the possibilities for miniaturization. The technology thus lays the foundation for continuous real-time communication down to the field level.

High-speed data transfer over longer distances

The many benefits mentioned above make Single Pair Ethernet particularly suitable for highly automated IIoT applications. The technology therefore forms the better alternative than conventional transmission paths in numerous industrial application scenarios. This is especially true for the production environment: due to advancing digitization and automation, ever larger amounts of data must be made available quickly and reliably on the store floor. In view of the growing production capacities in many places, larger distances often have to be overcome for data communication.

Single Pair Ethernet offers the optimum solution for this, as it allows comparatively high data transmission rates to be realized even over longer distances. In addition, for the first time, the technology enables continuous data exchange from the sensor to edge and cloud infrastructures via a uniform communication protocol. This considerably simplifies the management of network architectures.

As a flexibly deployable solution, Single Pair Ethernet can unfold its many advantages in all conceivable branches of industry. The more intensively processes are digitized and automated, the faster and smoother large volumes of data must flow on the store floor. For this reason, industries with a high degree of automation in particular benefit from the technology – such as automotive production, mechanical and plant engineering, the food and beverage industry, or the chemical and pharmaceutical industries. Single Pair Ethernet is also increasingly used in other application scenarios where fast and reliable data communication is required. These include transport and logistics, the smart city environment and defense.

Combining SPE cables with suitable connectors

However, SPE cabling can only unleash its full potential if it is combined with the right connectors. This is because the connection of the cable to the machine must be able to handle the high transmission speed accordingly. Fischer Connectors, for example, offers a wide-ranging portfolio of reliable complete SPE solutions. The Fischer Core and Fischer UltiMate™ series, for example, transmit data at a speed of 1 Gbit/s in accordance with IEEE 802.3bp – 1000Base-T1. They impress with their high robustness, safety, durability, as well as their environmental and mechanical resistance. The Fischer Single Pair Ethernet solutions comply with MIL-STD standards (for Fischer UltiMate™) and feature 10,000 mating cycles and three locking mechanisms (push-pull, screw, quick release). In addition to IP68/IP69 sealing rates, they also enable hermetic sealing.

High performance in a small space

Networked and highly automated IIoT production environments require maximum connectivity. High-performance cable infrastructures are needed that can transmit both power and data securely and efficiently over long distances and at high speeds. Since there is usually little space available on the store floor, and the networked devices and sensors are becoming smaller and smaller and are also difficult to access, a space-saving transmission technology is required. Single Pair Ethernet addresses these requirements precisely: high-speed data transfer in combination with low material usage and weight can take connectivity to a new level for a wide range of IIoT application scenarios.

Martin Wimmers, General Manager, Fischer Connectors Germany

Power and data mix: multipole low-voltage configurations enhance miniature and multifunctional connectivity

June 28, 2023 · 4 min read