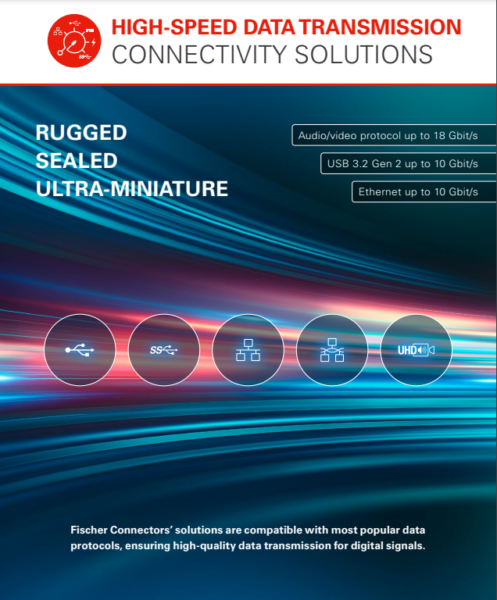

Data transmission plays an important role in modern medicine. The applications are diverse. Be it for precise imaging or diagnostic procedures, such as endoscopy, laparoscopy, electroencephalography (EEG), MRI and CT scanners or medical ultrasound. The connectivity technology is crucial here. Connectors and cables must not only be as compact as possible, but also robust, reliable and, last but not least, offer stable signal integrity. The increasing demand for high-speed applications must also be taken into account. The USB 3.2 Gen 2 standard with transfer rates of up to 10 Gbit/s is a particular focus here.

The connector must match the cable: How reliable high-speed data transmission succeeds in the medical sector

November 7, 2024 · 3 min readIn order to develop reliable and efficient connectivity solutions, especially for high-speed data transmission, expertise in cable assembly, high-performance connectors and the design, simulation and testing of signal integrity is essential. This is the only way to create solutions that meet all requirements. In addition to ubiquitous miniaturization and hygiene, which is particularly important for medical technology products, there are other factors that design engineers in particular need to take into account.

Flexibility

There is no one solution that can cover everything. USB 3.2 connectivity solutions are no different. In addition to size and configuration, the integration of a locking mechanism that fits the application plays a crucial role. For solutions that are in constant use and may be worn by patients, such as long-term ECGs, a locking mechanism that cannot be accidentally unplugged is suitable. Other solutions, on the other hand, rely on being able to be plugged and unplugged quickly and easily. In the operating theater in particular, it is important that the connection of camera systems and other instruments can be carried out easily by blind mating and simple handling, even when wearing gloves.

Solution providers must therefore offer different connectors for different applications – and ideally also be able to supply them in different configurations and designs. This starts with the material: brass, stainless steel or plastic. Every application has different requirements. In any case, it is important that the material is resistant to chemicals and suitable for sterilization processes. Sealing also plays a role. IP68 is the minimum, some connectors even offer IP69 and hermetic sealing through resin-sealed contact blocks, depending on the application.

The size of the connector and number of pins also affects the connection, e.g., 9 pins in a Ø 15.5 mm connector, 9 pins in a Ø 12.9 mm connector, or 12 signal and power pins in a Ø 14.9 mm connector. All are compatible with USB 3.2 specifications, but not all are suitable for every application. It is important to determine the right combination.

Stable signal integrity

But it’s not just the connector that is crucial when designing medical technology solutions. The cable assembly must also be carried out with the appropriate expertise. Engineers must consider numerous complex parameters in the design and characterization process, including impedance matching, line delay, insertion/return loss, crosstalk and EMC shielding.

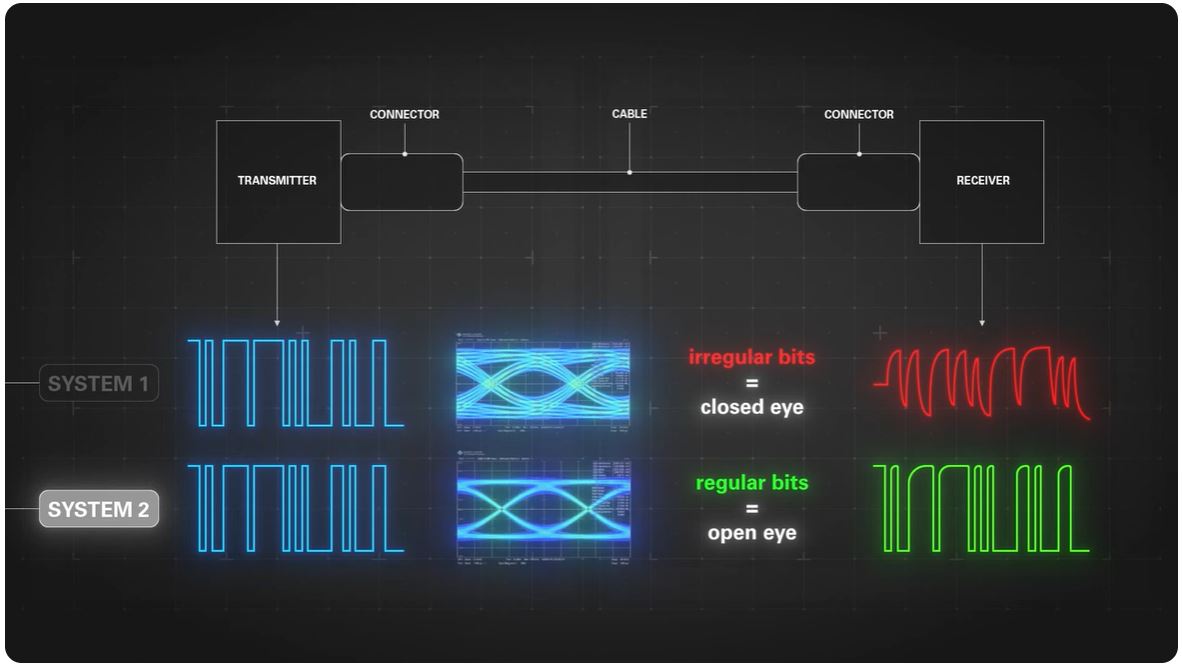

High-quality cable assembly ensures reliable data transmission, signal integrity and overall system function. For successful high-speed data transmission from transmitter to receiver, connectors and cables must be cross-optimized and undergo a series of compliance tests at the system level. USB 3.2 is a particularly demanding protocol where factors such as connector design, cable length, cable performance (loss), and controlled and repeatable cable assembly and potting processes are critical at transfer rates above 1 Gbit/s. It is also important to study the full physical layer of the link as part of a system test.

Although USB 3.2 opens up new possibilities for high-speed data transmission in medical applications, its potential can only be fully exploited if all components, i.e., connectors and cable assemblies, are perfectly matched to each other and to the planned application. Manufacturers and designers should therefore take care to select a solution provider that offers everything from a single source.

USB 3.2 is a particularly demanding protocol where signal integrity must be optimized through numerous tests in order to achieve a perfect result. On Fischer Connectors’ YouTube channel, view the educational video “Signal Integrity – simply explained”.

This may be of interest to you

Educational video: Signal integrity simply explained

September 11, 2024 · 4 min read