The most common hybrid combination being sought out by the engineering community is power and signal, and whether it’s all copper or a copper/fiber hybrid solution depends specifically on how much data needs to get through the cable.

End users ask manufacturers for simplicity and ease-of-use, while manufacturers try to keep production costs low and still maintain safety, reliability and quality standards. Moving from the older, larger connectors that handle only signal or only power to today’s smaller multi-tasking connectors that handle both power and signal comes with a bit of a learning curve. It is not a small task to satisfy everyone.

When a connector solution is mated and unmated on a daily – or more frequent basis – you have to take close look at the end use, the end user, and the environment. For instance, an end use in a hospital surgical environment where staff is wearing gloves is almost certainly going to need a different solution than someone handing military communications gear while wearing gloves. Both users are wearing gloves, but the similarity ends there. In addition to the gloves being different and therefore creating different challenges, the environments are different and the end users have different timeframes to plug/unplug connectors.

Here are a few tips to consider when moving to a traditional copper hybrid connector solution:

Look closely at the details:

- You know how many contacts you need. But you also need to know the exact size of each contact. Details become more important as voltage and current increases. A 0.5 mm contact will carry more power than a 0.3 mm contact. The smaller the contact, the lower the current, if you can run power at all. You risk an early connector failure if you try to run too much power through a contact that is too small to handle it.

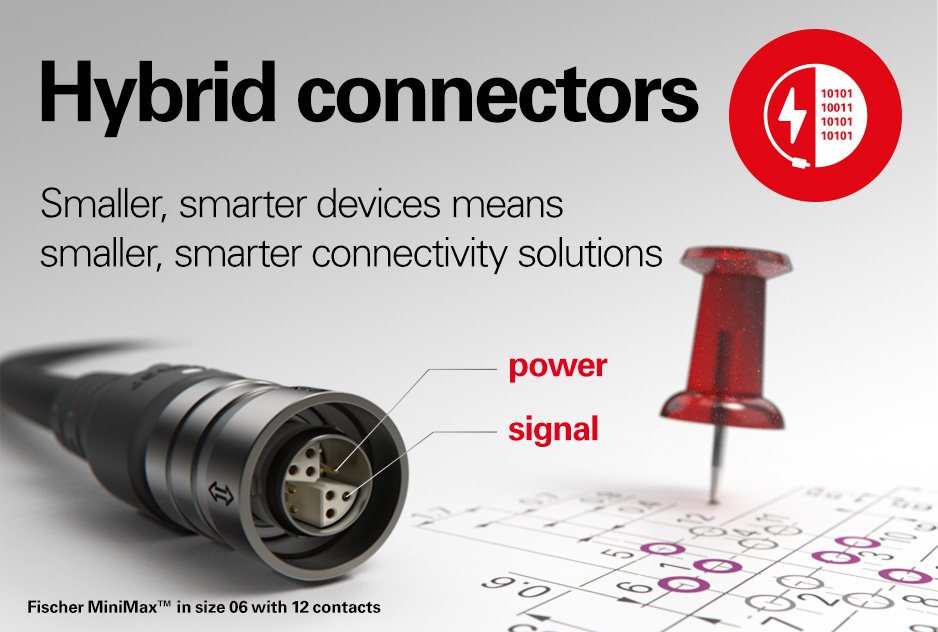

- Pin density and configuration itself is important. We believe the Fischer MiniMax™ Series is an ideal hybrid connector, with up to 24 pins that perform several functions including transmission of power, Ethernet, HDMI, etc., without interference. Yes, the cable plays an important role, but connectors need proper pin configurations to get the data speed you need. And in medical applications, proper creepage and clearance is important to minimize risk.

Cable configurations:

- Be sure your supplier knows which cables work best for your specific application. Not every cable with multiple twisted pairs is the same. If you are looking for a specific data speed, be sure that is in your specification.

- With today’s smaller connectors, make sure that the cable and connector actually fit together. It’s not so uncommon having people asking for cables that are too big for the connectors, and we end up recommending an alternative from stock that we know will work.

Fiber/copper hybrids

Working with hybrid connectors doesn’t end with traditional copper connectors. Fischer Connectors designs and builds fiber/copper hybrid connectors and cables for when you need to move a lot of data, and still need power. Playing off the popularity of SMPTE connectors in the broadcast world, newer, hybrid configurations with custom cable are available through both Fischer Connectors and fiber optic specialists such as Fischer Connectors’ partner FIS Blue.

The payoff

So what is the payoff? Our customers have been able to make substantial changes to designs by making hybrid connectors part of their solution. Replacing two connectors with one lowers the total cost of ownership by reducing the number of components purchased and inventoried. It simplifies design, makes the users more efficient, and maybe – just maybe – makes the engineer a little happier.

Fischer Connectors’ five product lines offer a wide range of hybrid connectors: power and signal, full copper or copper/fiber, all with various pin density & contact configurations. Other combinations such as power/fluid or power/air are also possible upon custom request. More information in our technical specifications: Volume 1 on Core, Volume 2 on UltiMate, FiberOptic, MiniMax, Freedom.