Numerous companies worldwide are now deploying medical device products containing the Fischer L.U.C, and are profiting from the many advantages offered by this unique connector solution. Applications currently in use include hand-held surgical devices, brain catheters, portable oxygen generators, peripheral vascular treatment systems, and cosmetic regenerative equipment. A major customer in Germany specified the Fischer L.U.C. for portable oxygen generators following Fischer’s ability to quickly deliver customized prototypes for faultless integration with their design solution. Another European customer wanted Fischer’s L.U.C. for a blood washing application because of the great modularity of configurations at the right price another for part of its optical surgery equipment while a customer in Asia thought the Fischer L.U.C. system to be a good fit for a disposal TV endoscope application.

“Years ago, we saw the medical industry moving towards low cost, disposable medical device applications,” says Daniel Spycher, International Sales Director, Fischer Connectors SA. “What makes the L.U.C. system so unique is its list of accommodating characteristics that appeal to the engineer tasked with designing a disposable medical device. It’s customizable, reliable, matable with metal receptacles, and possesses uncompromising performance.”

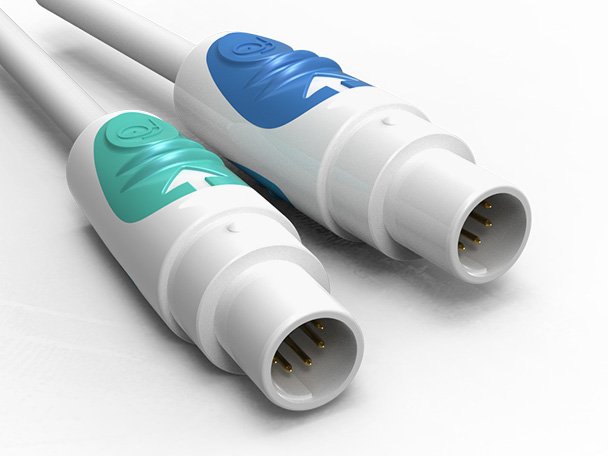

The Fischer L.U.C.™ customizable plastic interface shell is designed to accept standard contact block configurations, so engineers are not limited in determining what happens behind the interface connection. Hybrid connector configurations are also available to facilitate the integration of fluid and fibre optics, if desired. Electrical contacts can be mixed with fluid/gas contacts or POF (Polymer Optical Fibre) ideal for transmitting light. And for discerning environments, three colours are available to prevent mismating of critical connections.

Fischer Connectors also offers custom cable assembly solutions for manufacturers seeking an integrated connector and cable system. Off the shelf or customized cable solutions, low voltage or high voltage, fluid or hybrid, with cable termination, overmolding or heat shrinking are all standard offerings. Finally, Fischer Connectors offers a testing process for each cable assembly to ensure optimum reliability.