Choosing the right cable to use in any application depends on many parameters. One of the most important is its ability to thermally resist a maximum imposed current. To avoid over-dimensioning – which leads to higher costs, bigger space requirements and lower efficiency – finite element simulation is a good option. This is particularly true when dealing with heating problems caused by electrical resistance.

Engineering by digital simulation has become mainstream, helping engineers to solve increasingly complex problems while shortening the prototyping and testing stages. It enables them to better anticipate, understand and optimize the operation, development and design of many products. Above all, it has the advantage of covering a wide range of application domains, across multiple dimensional scales.

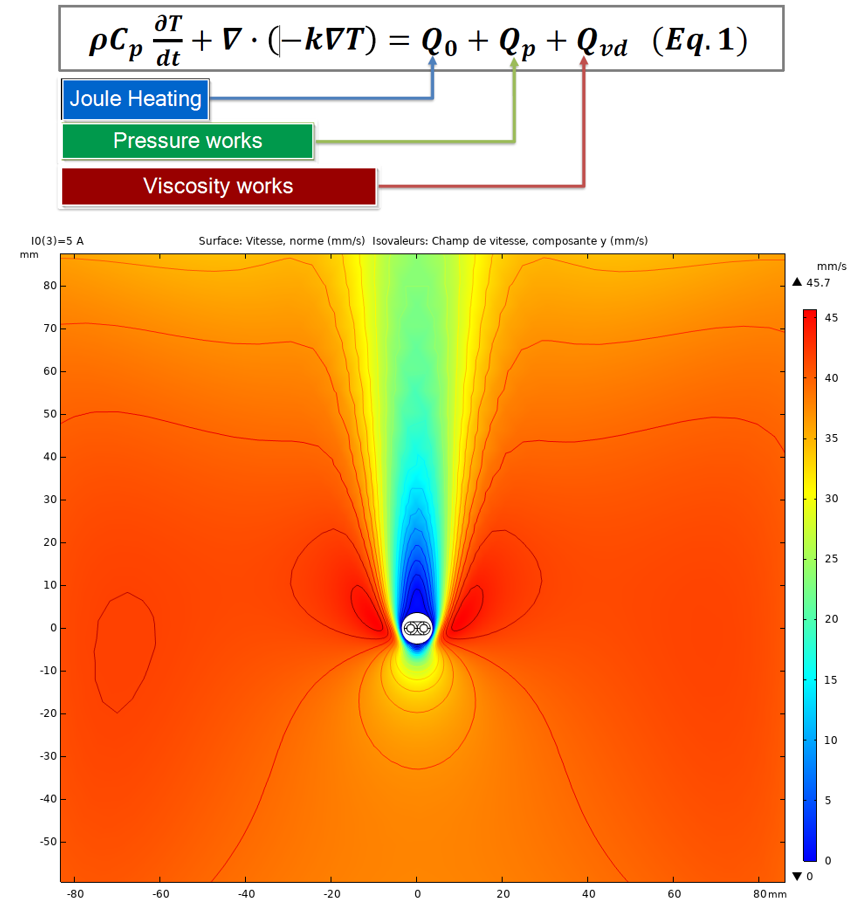

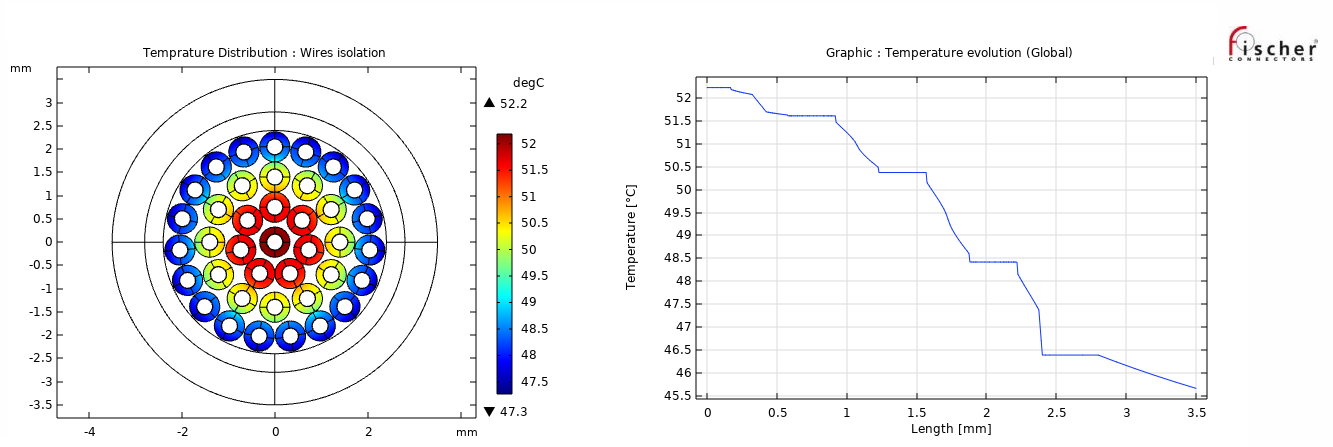

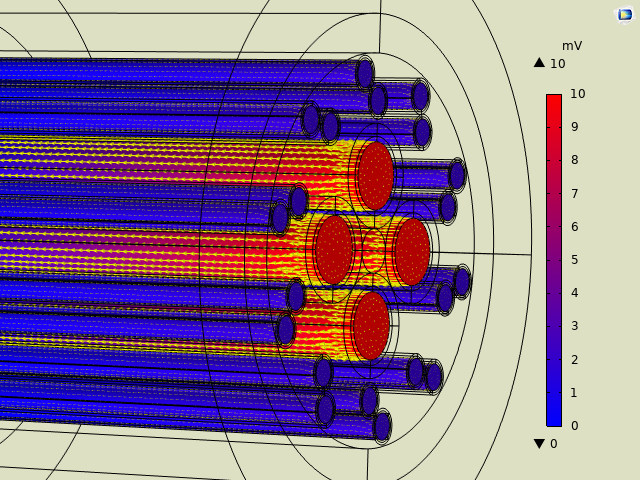

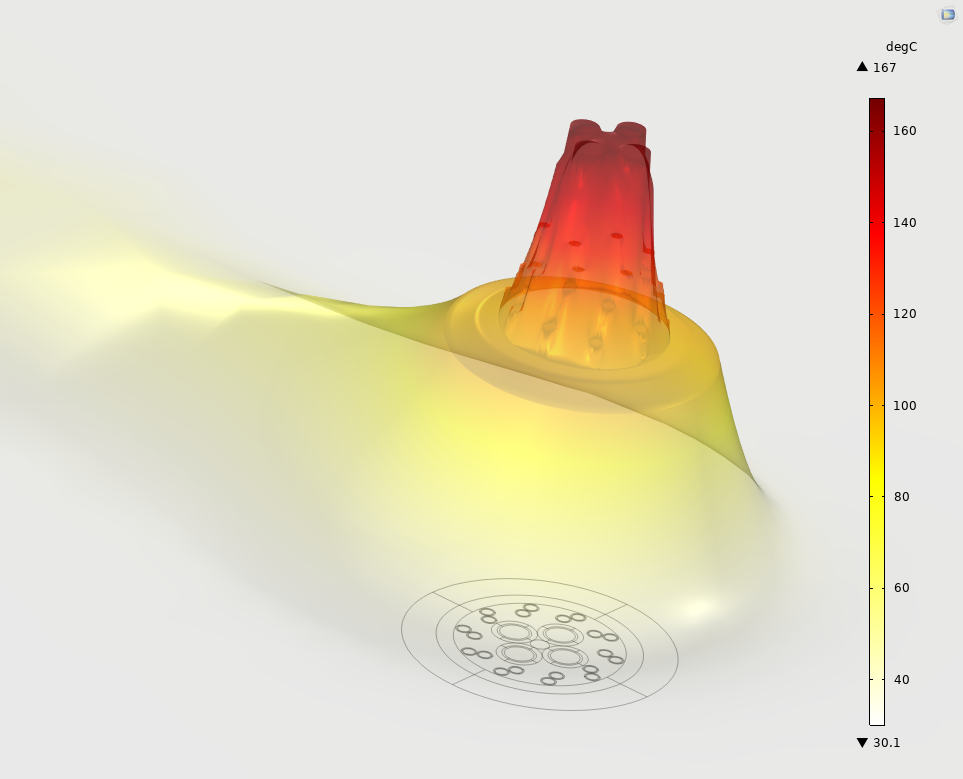

As far as the cable is concerned, it is known that its maximum use limit is determined by the heat resistance of its components. This aims to avoid any irreversible degradation that could endanger the system in which it is integrated. Nevertheless, implementing experimental procedures to better define the ins and outs of such a problem is work that takes considerable material resources. Using a multiphysics simulation software like COMSOL®, combined with application know-how, therefore brings real added value when resolving this type of problem, since it helps to better understand: the temperature behavior of the multiple components (strength member, fillers, binder wrap, jacket insulation, braided shield, etc.); the effect of the environment on the cable (type of environment, outside temperature, fluid velocity, etc.); as well as the characteristics of heat dissipation within the materials (heat transfer, fluid-solid exchange).

Process capabilities

Indeed, using such a tool, it is possible to determine the two-dimensional temperature distribution inside a cable for a multitude of geometrical configurations and load cases.